Page 125 - ProStar Product Guide

P. 125

™

ProStar Mild Steel Covered Electrodes

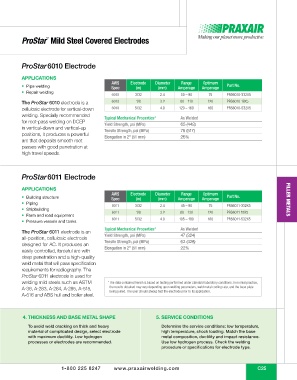

ProStar 6010 Electrode

APPLICATIONS

AWS Electrode Diameter Range Optimum

• Pipe welding Spec (in) (mm) Amperage Amperage Part No.

• Repair welding

6010 3/32 2.4 50 – 90 75 PRS6010-332X5

The ProStar 6010 electrode is a 6010 1/8 3.2 80 – 110 120 PRS6010-18X5

cellulosic electrode for vertical-down 6010 5/32 4.0 120 – 160 160 PRS6010-532X5

welding. Specially recommended

Typical Mechanical Properties* As Welded

for root-pass welding on DCEP

Yield Strength, psi (MPa) 65 (448)

in vertical-down and vertical-up

Tensile Strength, psi (MPa) 75 (517)

positions, it produces a powerful

Elongation in 2" (51 mm) 26%

arc that deposits smooth root

passes with good penetration at

high travel speeds.

ProStar 6011 Electrode

APPLICATIONS

AWS Electrode Diameter Range Optimum

• Building structure Part No.

Spec (in) (mm) Amperage Amperage FILLER METALS

• Piping

6011 3/32 2.4 45 – 90 75 PRS6011-332X5

• Shipbuilding

6011 1/8 3.2 80 – 130 120 PRS6011-18X5

• Farm and road equipment

6011 5/32 4.0 105 – 180 160 PRS6011-532X5

• Pressure vessels and tanks

Typical Mechanical Properties* As Welded

The ProStar 6011 electrode is an

Yield Strength, psi (MPa) 47 (324)

all-position, cellulosic electrode

Tensile Strength, psi (MPa) 62 (428)

designed for AC. It produces an

Elongation in 2" (51 mm) 22%

easily controlled, forceful arc with

deep penetration and a high-quality

weld metal that will pass specification

requirements for radiography. The

ProStar 6011 electrode is used for

welding mild steels such as ASTM * The data contained herein is based on testing performed under standard laboratory conditions. In normal practice,

A-36, A-283, A-284, A-285, A-515, the results obtained may vary depending upon welding parameters, weld metal cooling rate, and the base plate

being joined. The user should always test the electrode prior to its application.

A-516 and ABS hull and boiler steel.

4. THICKNESS AND BASE METAL SHAPE 5. SERVICE CONDITIONS

To avoid weld cracking on thick and heavy Determine the service conditions: low temperature,

material of complicated design, select electrode high temperature, shock loading. Match the base

with maximum ductility. Low hydrogen metal composition, ductility and impact resistance.

processes or electrodes are recommended. Use low hydrogen process. Check the welding

procedure or specifications for electrode type.

1-800 225 8247 www.praxairwelding.com C25