Page 129 - ProStar Product Guide

P. 129

ProStar Stainless Steel Welding

™

ER308L DESIGNATION SYSTEM FOR STAINLESS STEEL

Suffix Additional Requirements

L Lower carbon content

Electrode Weld chemistry Indicates any changes LSi Lower carbon content, higher silicon

or rod from this electrode to the original alloy

308L is used to weld Type 300 stainless steel (301, 302, 309LSi is a silicon-enhanced grade of 309L, which

304) but can also be used to weld many other austenitic improves welding properties such as wetting. It has

chromium nickel alloys of the 18Cr-8%Ni type. Used good general corrosion resistance.

extensively in the welding of chemical plant equipment.

316L is used for welding 316 stainless steel and should

308LSi is a silicon-enhanced product that significantly be used on weldments intended for high-temperature

increases wetting action, resulting in a smooth weld and service such as food service applications.

improved weldability and performance on 304 steel.

316LSi is high silicon grade of 316L. The addition of

309L is used for welding carbon and low-alloy steel to silicon improves weldability and performance.

stainless steel. This can be done, provided the service

temperature does not exceed approximately 700 ºF

(315 ºC). Post-weld heat treatment should only be ProStar GMAW wires feature a controlled surface,

mechanical shape, and chemistry that provides a

performed after due consideration.

consistent, stable arc with low spatter and low wear

on liners and contact tips.

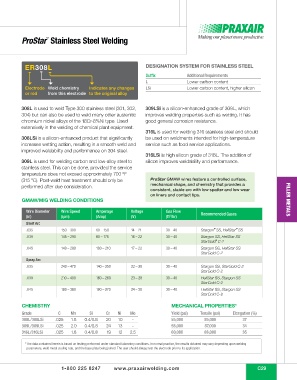

GMAW/MIG WELDING CONDITIONS FILLER METALS

Wire Diameter Wire Speed Amperage Voltage Gas Flow

3

(in) (ipm) (Amp) (V) (ft /hr) Recommended Gases

Short Arc

® ®

® ®

.035 150 – 300 60 – 150 14 – 21 30 – 40 Stargon SS, HeliStar SS

.039 145 – 290 80 – 175 16 – 22 30 – 40 Stargon SS, HeliStar SS

®

StarGolddd C-2

.045 140 – 280 100 – 210 17 – 22 30 – 40 Stargon SS, HeliStar SS

StarGold C-2

Spray Arc

.035 240 – 470 140 – 250 22 – 28 30 – 40 Stargon SS, StarGold C-2

StarGold C-2

.039 210 – 400 160 – 260 23 – 28 30 – 40 HeliStar SS, r Stargon SS

StarGold C-2

.045 190 – 360 180 – 270 24 – 30 30 – 40 HeliStar SS, r Stargon SS

StarGold C-2d

CHEMISTRY MECHANICAL PROPERTIES*

Grade C Mn Si Cr Ni Mo Yield (psi) Tensile (psi) Elongation (%)

308L/308LSi .025 1.8 0.4/0.8 20 10 - 55,000 85,000 37

309L/309LSi .025 2.0 0.4/0.8 24 13 - 58,000 87,000 34

316L/316LSi .025 1.8 0.4/0.8 19 12 2.5 60,000 88,000 35

* The data contained herein is based on testing performed under standard laboratory conditions. In normal practice, the results obtained may vary depending upon welding

parameters, weld metal cooling rate, and the base plate being joined. The user should always test the electrode prior to its application.

1-800 225 8247 www.praxairwelding.com C29