Page 225 - Praxair Productivity Catalog

P. 225

Stargon Welding Gases

Performance Characteristics

Praxair’s Stargon AL

™

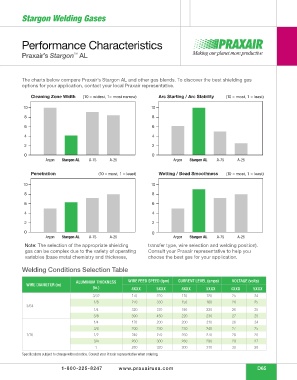

The charts below compare Praxair’s Stargon AL and other gas blends. To discover the best shielding gas

options for your application, contact your local Praxair representative.

Cleaning Zone Width (10 = widest, 1= most narrow) Arc Starting / Arc Stability (10 = most, 1 = least)

10 10

8 8

6 6

4 4

2 2

0 0

Argon Stargon AL A-75 A-25 Argon Stargon AL A-75 A-25

Penetration (10 = most, 1 = least) Wetting / Bead Smoothness (10 = most, 1 = least)

10 10

8 8

6 6

4 4

2 2

0 0

Argon Stargon AL A-75 A-25 Argon Stargon AL A-75 A-25

Note: The selection of the appropriate shielding transfer type, wire selection and welding position).

gas can be complex due to the variety of operating Consult your Praxair representative to help you

variables (base metal chemistry and thickness, choose the best gas for your application.

Welding Conditions Selection Table

ALUMINUM THICKNESS WIRE FEED SPEED (ipm) CURRENT LEVEL (amps) VOLTAGE (volts)

WIRE DIAMETER (in)

(in.) 4XXX 5XXX 4XXX 5XXX 4XXX 5XXX

3/32 170 220 110 120 25 24

1/8 270 330 150 160 26 25

3/64

1/4 320 370 190 220 26 25

3/8 390 450 220 230 27 25

1/4 170 200 200 210 26 24

3/8 200 230 230 240 27 25

1/16 1/2 240 270 260 270 28 26

3/4 260 300 280 290 29 27

1 280 320 300 310 30 28

Specifi cations subject to change without notice. Consult your Praxair representative when ordering.

1-800-225-8247 www.praxairusa.com D65