Page 221 - Praxair Productivity Catalog

P. 221

Mechanized Orbital Welding

Gas Management

& Auxiliary Equipment

Precision purging is essential for controlling weld quality, particularly Maintain Weld

when welding high-alloy, corrosion-resistant materials that are extremely

sensitive to oxygen in the welding process. Quality During the

OXY Process

Precise purging helps

you control weld quality

when using oxygen in

7 ppm (0.0007%) 27 ppm (0.0027%) 500 ppm (0.05%)

the welding process

* Compatible controller required. Contact your Praxair representative to discuss your application.

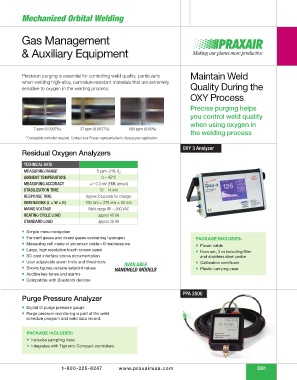

OXY 3 Analyzer

Residual Oxygen Analyzers

TECHNICAL DATA

MEASURING RANGE 5 ppm -21% O 2

AMBIENT TEMPERATURE 0 – 45°C

MEASURING ACCURACY +/- 0.3 mV (EMK sensor)

STABILIZATION TIME 10 – 14 min

RESPONSE TIME Approx 2 seconds for changer

DIMENSIONS (L × W × H) 190 mm × 270 mm × 55 mm

MAINS VOLTAGE Multi-range 90 – 260 VAC

HEATING CYCLE LOAD approx 40 VA

STANDARD LOAD approx 20 VA

Simple menu navigation

For inert gases and mixed gases containing hydrogen PACKAGE INCLUDES:

Measuring cell made of zirconium oxide—0 maintenance Power cable

Large, high resolution touch screen panel Hors set, 3 m including fi lter

SD card interface stores documentation and stainless steel probe

User adjustable alarm limits and thresholds AVAILABLE Calibration certifi cate

Shows fi gures outside setpoint values HANDHELD MODELS Plastic carrying case

Audible key tones and alarms

Compatible with Bluetooth devices

PPA 2500

Purge Pressure Analyzer

Digital ID purge pressure gauge

Purge pressure monitoring is part of the weld

schedule program and weld data record.

PACKAGE INCLUDES:

Includes sampling hose

Integrates with Tigtronic Compact controllers

1-800-225-8247 www.praxairusa.com D61