Page 227 - Praxair Productivity Catalog

P. 227

Stargon Welding Gases

Performance Characteristics

Praxair’s Stargon SS

™

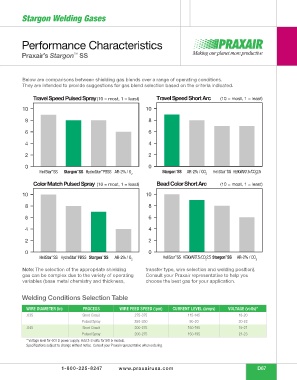

Below are comparisons between shielding gas blends over a range of operating conditions.

They are intended to provide suggestions for gas blend selection based on the criteria indicated.

Travel Speed Pulsed Spray(10 = most, 1 = least) Travel Speed Short Arc (10 = most, 1 = least)

10 10

8 8

6 6

4 4

2 2

0 0

HeliStar SS Stargon SS HydroStar PBSS AR-2% / O Stargon SS AR-2% / CO HeliStar SS HE90/AR7.5 /CO 2.5

™

™

™

™

™

2 2 2

Color Match Pulsed Spray (10 = most, 1 = least) Bead Color Short Arc (10 = most, 1 = least)

10 10

8 8

6 6

4 4

2 2

0 0

HeliStar SS HydroStar PBSS Stargon SS AR-2% / O HeliStar SS HE90/AR7.5 /CO 2.5 Stargon SS AR-2% / CO

™

™

™

™

™

2 2 2

Note: The selection of the appropriate shielding transfer type, wire selection and welding position).

gas can be complex due to the variety of operating Consult your Praxair representative to help you

variables (base metal chemistry and thickness, choose the best gas for your application.

Welding Conditions Selection Table

WIRE DIAMETER (in) PROCESS WIRE FEED SPEED (ipm) CURRENT LEVEL (amps) VOLTAGE (volts)*

.035 Short Circuit 275-375 115-145 18-20

Pulsed Spray 250-350 90-20 20-22

.045 Short Circuit 200-275 150-195 19-21

Pulsed Spray 200-275 150-195 21-23

* Voltage level for 60 Hz power supply. Add 2-3 volts for 50Hx models.

Specifi cations subject to change without notice. Consult your Praxair representative when ordering.

1-800-225-8247 www.praxairusa.com D67