Page 222 - Praxair Productivity Catalog

P. 222

Welding Gases

Stargon VS Welding Blend for Carbon Steel

™

High deposition rates and excellent weld quality for carbon steel MIG welding

Praxair’s Stargon VS is a proprietary blend of argon, helium, and carbon dioxide, designed to meet the demands of your

MIG/MAG (GMAW) process with enhanced performance and lower operational costs. Stargon VS gas blend provides

high arc energy which stabilizes the arc and allows maximum wire transfer rates and travel speeds, focused penetration

and excellent bead appearance – good wetting, fl at crown and minimal spatter.

Formulated for Higher Effi ciency and Productivity C-25

Stargon VS as compared to common shielding gases C-25 and 90/10 under

the same conditions: 70S-6 .035 wire, 3/16 in. fi llet weld. The results speak

for themselves.

C-25 C-10 Stargon VS Gas Blend

Wire feed speed: 450 Wire feed speed: 600 Wire feed speed: 750

C-10

Voltage: 19.5 Voltage: 22.0 Voltage: 26.5

Deposition: 7.4 lbs./hr Deposition: 9.8 lbs./hr Deposition: 12.3 lbs./hr

Decreased spatter and increased travel Highly stabilized weld when compared

Somewhat erratic arc with speed compared to C-25, but shows to C-25 & C-10, completed 20% faster

a large amount of spatter silicon deposits on the weld surface and than C-10, and completed 40% faster

some undercutting at weld toes than C-25 in CV

Shielding gases have natural limits on deposition. C-25 gas lacks enough Stargon VS Gas Blend

energy in the arc to stabilize the weld at high deposition rates, leading to

spatter and undercutting. Although 90/10 is able to match Stargon VS’s

12.3 lbs./hr deposition rate, the quality is diminished by spatter and crowning.

If your project calls for a fl at, clean weld at maximum wire feed and

deposition rate, Stargon VS is the optimal choice.

Increase Throughput, Activity,

and Your Bottom Line

When welding with a 15% duty cycle, Praxair’s Stargon VS gas

produced 15 parts per hour, a 20% increase in productivity over

90/10 and a 40% increase when compared to C-25.

Stargon VS Blend Performance

Excellent arc stability, wetting and weldability at low and

high amperages

Helium allows for exceptional heat transfer

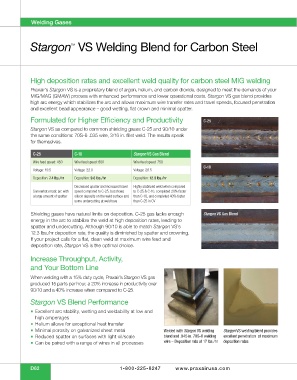

Minimal porosity on galvanized sheet metal Welded with Stargon VS welding Stargon VS welding blend provides

Reduced spatter on surfaces with light oil/scale blend and .045 in. 70S-6 welding excellent penetration at maximum

Can be paired with a range of wires in all processes wire – Deposition rate of 17 lbs./hr deposition rates

D62 1-800-225-8247 www.praxairusa.com