Page 153 - ProStar Product Guide

P. 153

™

ProStar Chemicals continued

ProStar Cooling Fluids

Inhibited blends of deionized filtered water and glycol. Designed

for use in MIG, TIG, plasma and resistance welding systems

to cool and protect equipment. One gallon (3.78 litre) size.

Part No. Description

Ethylene Glycol Based

PRS50200 Regular temperature +19 °F (-7 °C)

PRS50201 Mild temperature +6 °F (-14 °C)

PRS50202 Low temperature -32 °F (-35 °C)

Propylene Glycol Based

PRS50204 Safe Cool Fluid temperature +10 °F (-12 °C)

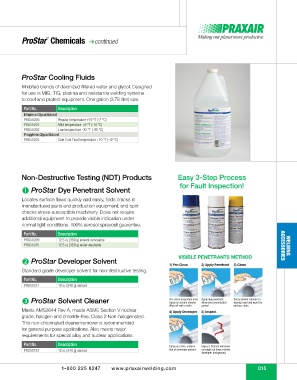

Non-Destructive Testing (NDT) Products Easy 3-Step Process

for Fault Inspection!

n ProStar Dye Penetrant Solvent

Locates surface flaws quickly and easily, finds cracks in

manufactured parts and production equipment, and spot

checks stress-susceptible machinery. Does not require

additional equipment to provide visible indication under

normal light conditions. 100% aerosol sprayout guarantee.

Part No. Description

PRS50209 12.5 oz (350 g) solvent removable

PRS50210 12.5 oz (350 g) water washable ACCESSORIES WELDING

VISIBLE PENETRANTS METHOD

o ProStar Developer Solvent

1) Pre-Clean 2) Apply Penetrant 3) Clean

Standard grade developer solvent for non-destructive testing.

Part No. Description

PRS50211 12 oz (340 g) aerosol

p ProStar Solvent Cleaner Pre-clean inspection area. Apply dye penetrant. Spray solvent cleaner on

Allow short penetration

Spray on solvent cleaner.

wiping towel and wipe the

Wipe off with a cloth. period. surface clean.

Meets AMS2644 Rev A, meets ASME Section V nuclear 4) Apply Developer 5) Inspect

grade, halogen and chloride-free, Class 2 Non-halogenated.

This non-chlorinated cleaner/remover is recommended

for general purpose applications. Also meets major

requirements for special alloy and nuclear applications.

Part No. Description

Spray on a thin, uniform Inspect. Defects will show

PRS50212 12 oz (340 g) aerosol film of developer solvent. as bright red lines in white

developer background.

1-800 225 8247 www.praxairwelding.com D15