Page 105 - ProStar Product Guide

P. 105

Clean Materials, Stringent Controls

™ ™

ProStar twist-free welding wire starts as pickled green design helps to ensure, maintain, and deliver twist-free

rod coils produced under ISO-certified control to some performance, weld after weld.

of the tightest batch-to-batch tolerances in the industry.

The result is a wire product featuring reliable feeding and

Our proprietary drawing and coppering processes result predictive welding performance that is consistent from

in fewer scratches with less flaking or peeling to produce pack to pack. This means less downtime due to clogged

an extremely clean and smooth wire surface. liners, unevenly worn consumables, and feed issues; less

over-welding due to predictable placement of the weld

ProStar wire is packaged using our proprietary, twist-

puddle; and reduced overall weld cost-per-foot.

free winding machines. Innovative bulk packaging

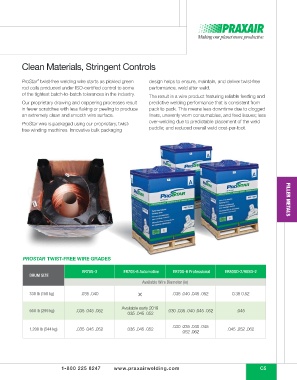

PROSTAR TWIST-FREE WIRE GRADES FILLER METALS

ER70S-3 ER70S-6 Automotive ER70S-6 Professional ER80SD-2/90SD-2

DRUM SIZE

Available Wire Diameter (in)

330 lb (150 kg) .035 .040 × .035 .040 .045 .052 0.35 0.52

Available early 2019

660 lb (299 kg) .035 .045 .052 .030 .035 .040 .045 .052 .045

.035 .045 .052

.030 .035 .040 .045

1,200 lb (544 kg) .035 .045 .052 .035 .045 .052 .045 .052 .062

.052 .062

1-800 225 8247 www.praxairwelding.com C5