Stargon™ SS for Stainless Steel

Avoid Rising Helium Costs, While Improving GMAW Welding Quality on Stainless Steel

Replace Expensive Helium Welding Blends

The world’s supply of helium is finite and with a growing demand, prices continue to climb. When MIG welding stainless steel, helium’s thermal conductive properties help to produce fine and flat welds. Stargon™ SS shielding gas blend is able to duplicate the arc characteristics of helium welding blends with its unique composition, while offering significant cost savings.

Versatile Blend for All Stainless Steel GMAW Welding Processes

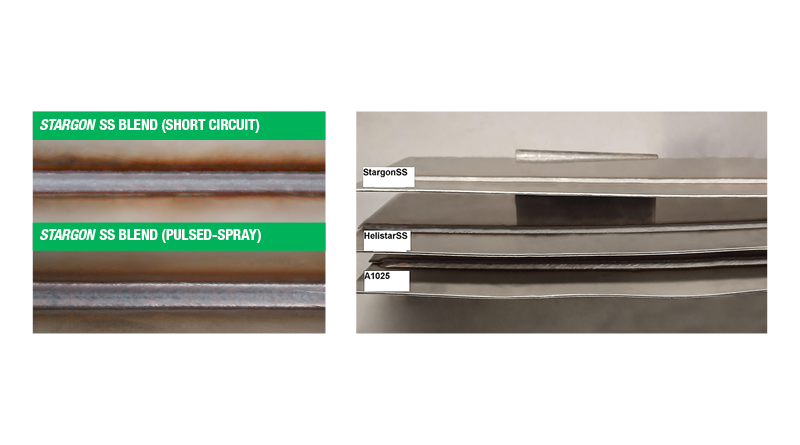

Linde’s Stargon SS welding gas blend is a carefully controlled blend of argon, carbon dioxide and nitrogen. It is designed for welding a variety of thick or thin stainless steels in all positions and performs well in short circuit, spray and pulsed spray welding modes.

Features and Benefits

Nitrogen-enhanced welding shielding gas blend

- Excellent welding arc stability

- Good weld penetration and surface appearance

- Chemistry control for strong corrosion resistance

- Reduced base metal distortion

Low oxidizing potential

- Controlled CO2 level for reduced weld carbon content, resulting in improved corrosion resistance

- Improved color match

Good performance over a wide range of welding parameters

- Good short-circuit welding performance

- Optimized welding travel speed performance in pulsed spray

- Good bead shape with minimal spatter

Excellent mechanical properties

- Equivalent or greater tensile strengths

- Equivalent or greater corrosion resistance

Exceptional GMAW Welding Performance on Thin Materials

Linde’s argon-based Stargon SS shielding gas blend doesn’t require higher arc voltages like helium-based blends. High arc voltages increase heat input into the weld, which affects product quality when welding thin materials.

Stargon SS blend allows for lower welding voltages, compared to helium blends. This means less heat input during welding, resulting in less metal distortion. Lower heat input using Stargon SS blend also decreases sensitization

of the chrome in the weld, thus improving corrosion resistance in the weldment. This makes Stargon SS blend an ideal blend for sheet metal and thin-gauge applications.