ProStar™ 24/7 System

Eliminate Cell Downtime with Continuous Delivery of Welding Wire to the Robotic Cell

Eliminate Cell Downtime Caused by Manual Welding Wire Changeouts

Linde's 24/7 wire feed system helps improve and protect the productivity of your robotic MIG welding cells. Each “wire farm” consists of two 1,200 pound drums of ProStar™ wire, the 24/7 system swing arm and stand, RW 24/7 butt welder and 24/7 die.

24/7 System Components

Linde's 24/7 welding wire feed system is designed to serve a robotic cell sequentially from two wire drums — enabling continuous delivery of welding wire and avoiding downtime.

| Burr Shaver (GMAW) | Dia. 0.035 in. | Dia. 0.040 in. | Dia. 0.045 in. | Dia. 0.047 in. | Dia. 0.052 in. | Dia. 0.062 in. |

| PRS1010.100 | PRS1010.100-035 | PRS1010.100-040 | PRS1010.100-045 | PRS1010.100-047 | PRS1010.100-052 | PRS1010.100-062 |

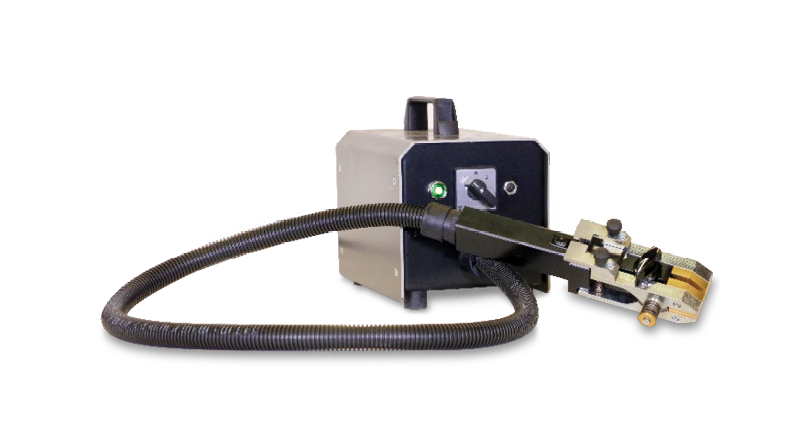

24/7 Butt Welder

Joins mild steel wires of various diameters. Set the welding current to Position One for .030 to .062 diameter wires. Select Position Two to weld 5/64 to 5/32 diameter wire.

24/7 Swing Arm

Prior to the first drum being spent, its wire end is welded to wire start in the full drum. As the welding wire source transitions from drum to drum, the swing arm simultaneously rotates to supply wire from the full drum.

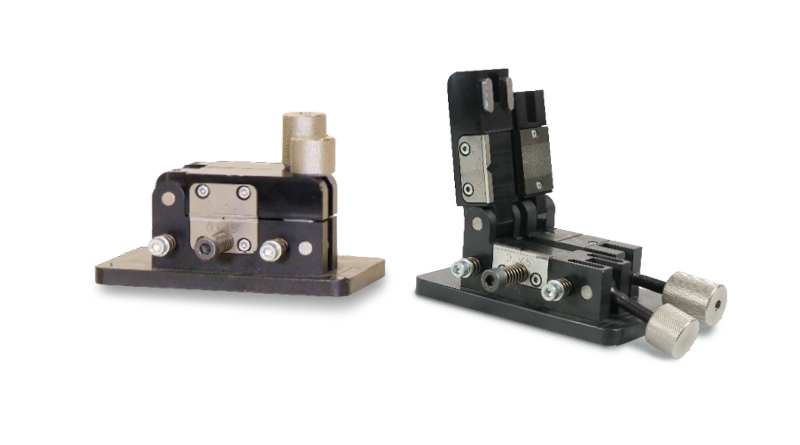

24/7 Die Set

With shaving plates available for many welding wire diameters, the 24/7 die set ensures a consistent diameter across the welded seams when drums are joined together by removing the resultant fl ash and any burrs from the welding process.