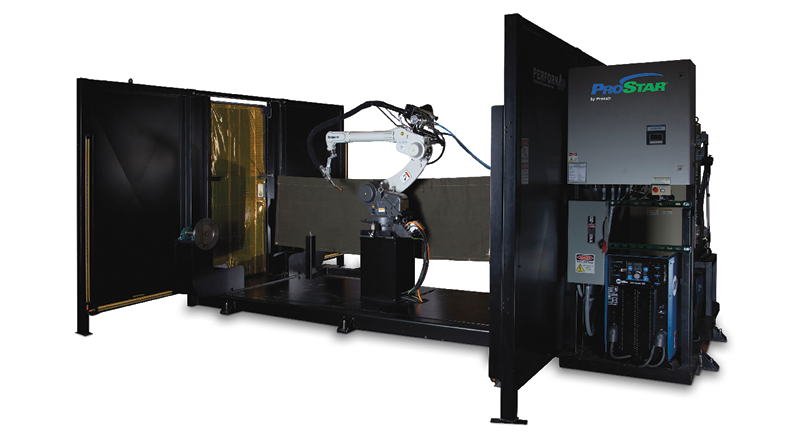

PerformArc® 1100SS, 2200SS Robotic Welding Cell

Extremely High Productivity

Station indexing time is eliminated, allowing the robot to immediately begin welding on station B when station A is complete, gaining efficiencies and maximizing valuable time. A second robot can be added, doubling throughput without requiring additional floor space. Standard load station jog provides complete load position flexibility, allowing multi-stage loading or tack and finish welding to occur in a common welding fixture.

Manufacturing Flexibility

Our pre-engineered system is pre-wired and pre-assembled with a fully-welded frame. It’s shipped to you in three sections for quick assembly and connection. The PRS1100SS features an open side wall for easy changeover of holding fixtures or weldments by crane or forklift. For ever-changing production needs, the large rotation diameter and heavy payload capacity allow low-, mid- and high volumes to be welded in single, multiple or progressive fixtures. Single- or dual-sided operation minimize interruptions and maximize throughput by allowing fixtures or parts to be changed while welding is occurring on the opposite side.

Standard Features

- 6 kg arc welding robot

- 64-bit controller with TFT color display teaching pendant utilizing Windows® CE

- Auto-Continuum™ Advanced MIG Welding System

- Auto-Continuum wire drive motor assembly

- Tregaskiss™ air-cooled welding torch

- Miller designed and manufactured total productivity system

System Features

- (2) Integrated operator interfaces (E-Stop, Auto, Servo On, Hold, Start, Position Jog)

- (1) Full open hinged door for maintenance access

- TCP pointer and resident TCP check program

- Tip change monitor and maintenance program for easy torch upkeep

- Arc start retry, arc overlapping, flying arc start, password protection

- Resume function, shifting functions, online help function

- Standard remote axis jog (unlimited positional jog at operator load station)

Standard Configuration

| Part No. | Frame Width | Frame Depth | Frame Height | Rotation Height (from floor) | Rotation Diameter | Headstock-Tailstock Span | Distance From Rotation to Light Curtain CL | Light Curtain Opening | Robot Height (from floor) | Robot Distance (from CL or Rotation) | Positioner CL to Positioner CL | Robot CL to Positioner Faceplate | Controls Area Width | Controls Area Depth | Shipping Weight Main Base | Shipping Weight Wing Pallet |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | |

| PerformArc® 110SS | 200 in. | 168 in. | 90 in. | 33 in. | 44 in. | 120 in. | 19 in. | 150 in. | 31 in. | 37 in. | 74 in. | 60 in. | 90 in. | 32 in. | 6,800 lbs. | 600 lbs. |

| PerformArc® 220SS | 200 in. | 197 in. | 90 in. | 37 in. | 60 in. | 120 in. | 17.5 in. | 153 in. | 43 in. | 45 in. | 91 in. | 60 in. | 90 in. | 36 in. | 3,000 lbs. | 600 lbs. |

*Note: All dimensions are approximate

Positioner General Technical Specifications

| 1100SS | 2200SS | |

|---|---|---|

| Model | Servo Positioner | Servo Positioner |

| Motor Type | 1.6 kW AC Digital Servo | 3.5 kW AC Digital Servo |

| Control Type | Servo Control | Servo Control |

| Payload (per side) | 1,100 lbs. | 2,200 lbs. |

| Payload Offset (from positioner CL) | Please consult manual | Please consult manual |

| Through Hole (for utility pass through) | 2.16 in. | 2.95 in. |

Tooling Area Options

| Part No. | 1100SS | 2200SS |

|---|---|---|

| Standard Headstock-Tailstock Width | 120 in. | 120 in. |

| Standard Rotation Diameter | 44 in. | 70 in. |

| Optional Headstock-Tailstock Widths | 96 in., 144 in. | 96 in., 144 in. |

| Optional Rotation Diameter | - | 60 in. |

| Optional Payload | Available upon request | Available upon request |

Robot Options

| 1100SS Single | 1100SS Dual Robot | 2200SS Single | 2200SS Dual Robot |

|---|---|---|---|

| TM1600 | TM1400 | TM1600 | TM1600 |

| TM1800 | TM1600 | TM1800 | TM1800 |

| TM2000 | TM1800 | TM2000 | TM200 |

Power Source Options

| Advanced MIG (GMAW) | TIG (GTAW) |

| Auto-Continuum™ 350A / 500A | Dynasty® 400A |

| TAWERS 350A / 4505A | Dynasty® 800A |

| BPA-300A |