Gas Handling Equipment

Equipment for Specialty Gases

Role of Specialty Gas Equipment in your gas applications. All the care that has been taken to provide a calibration mixture’s stability or a specified maximum impurity

level in your high purity gases should not be jeopardized by using improper equipment. The equipment has to respond to all functional, safety and quality aspects of the corresponding gas application.

Linde has decades of experience in

the sourcing, equipment selection, assembly and installation of gas handling systems as used in laboratories, universities and research, semiconductor, chemical, pharmaceutical and many other high demanding industries.

Functional aspects

For safety and local regulations, Gas Cylinders are mostly installed at a central location. The gas or gas mixture should be transferred from the cylinder to the point of use, not only at the specified pressure and flowrate but also with its original specifications.

Safety aspects

Starting from the high pressure in the gas cylinder, the equipment has to provide a constant reduced pressure at the point of use, while assuring leak tightness to avoid contamination of the work environment by the characteristics of the gases in use (flammability, toxicity, corrosivity).

Quality aspects

Intrusion of ambient impurities, for example O2 and H2O (retro-diffusion), in a gas handling system will lead to deterioration of the stability of certain calibration mixtures and contamination of high purity gases. Leak tightness of the equipment and the overall installation (piping, connection points, welded joints, etc.) should be verified.

Equipment Program

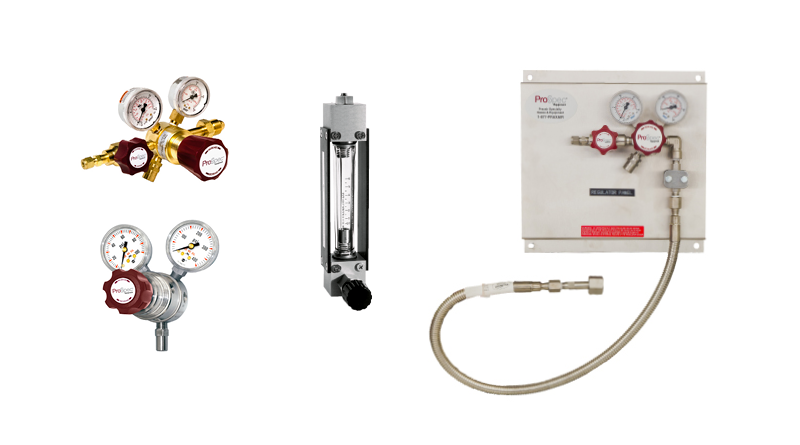

A comprehensive program covers all basic requirements for the safe and qualitative handling of all your specialty gas applications. It includes a range of pressure regulators (single stage and double stage) panels based on the gas type, switch-over systems, and point-of-use regulators. In addition, Linde can source all the necessary equipment for your gas uses, including gas filters, flow meters, controllers and Cryogenic Apparatus.

Pressure regulators

Available in single stage and double stage design, the latter being used in applications where constant outlet pressure is required independent of decreasing inlet pressure.

- Critical purity: These stainless steel and Brass Regulators are used where purity and contamination requirements are critical. They are typically used with high purity gases and toxic or flammable gases.

- High Purity: These nickel-plated brass/stainless steel regulators are used for applications where diffusion resistance is an important factor in ensuring purity.

- High Purity Economical: These chrome-plated brass regulators have similar features to the high purity series. They are most often used with high purity gases when higher flow rates are required and cost is the most important issue.

Gas Distribution Panels

Linde offers standard solutions that cover most of the gas applications: wall mount design, connection with the cylinder by a stainless steel winded (“pigtail”) or flexible tubing.

- Panel to connect one cylinder of an inert non flammable gas of medium quality. Without purging capability.

- Panel to connect one cylinder of an inert or flammable gas of medium to high quality. With purging capability using the connected gas.

- Panel to connect one cylinder of a toxic, corrosive or flammable gas of medium to high quality. With cross purging capability using an inert assist gas (typically N2 6.0).

In addition, Linde can source fully enclosed gas cabinets for hazardous gases in compliance with local safety codes.

Switchover Systems

Linde also offers a sas supply panel for connecting two times one cylinder, with automatic switchover for continuous gas supply. It is extendable to connect more cylinders at each side for gases and gas mixtures of medium to high purity and equipped with process-gas purging. These switchover stations can be equipped with a power supply/remote alarm to provide both local and remote indication of status.