Gas Delivery Systems

Equipment that Delivers

Linde designs and builds a wide range of gas delivery systems to fit your application needs. From changeover systems and switchovers to control panels and manifolds, we have what you need to optimize your gas delivery.

See below for an overview of our gas delivery systems, then visit the Gas Equipment section of our catalog for details on the products we sell.

Bulk Gas Delivery Systems

We’re revolutionizing flow rates for ammonia as well as many other specialty gases. With our SureFlow™ Bulk Specialty Gas Supply Systems and Controllers,

we are significantly reducing the number of cylinder changeouts required by conventional systems — leading to improvements in uptime, production costs, purity levels and safety.

Our enclosed heating system and new silicone rubber heat blanket system allow for higher flow rates while maintaining controlled external ton container temperatures. These systems can be skid mounted to facilitate installation and movement around the facility, and can deliver continuous ammonia flows of 600slpm with peaks greater than 3000slpm.

Control Panels

Critical Purity Manifolds

Critical Purity Automatic Switchovers

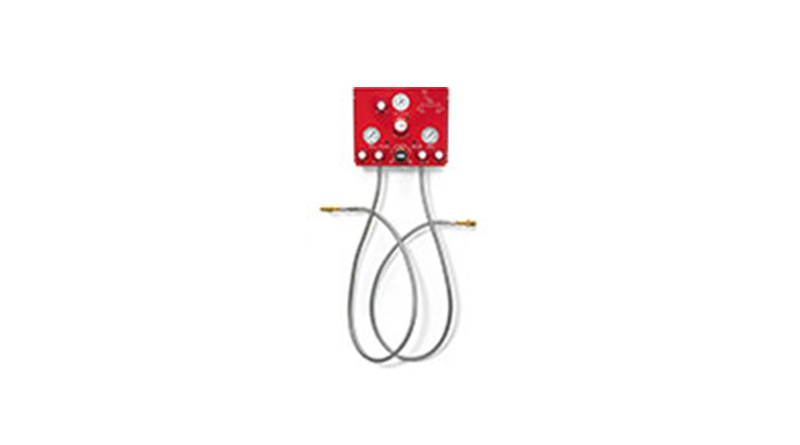

Dewar & High Pressure Cylinder Changeover System

The ProStar™ Platinum Series 8000 Automatic Dewar and High Pressure Cylinder Changeover System is designed to provide an uninterrupted flow of gas from two sources. When one source is in service, the other source is on standby. When the source is depleted, the changeover to the standby source occurs automatically. Once the changeover has occurred, a gas technician replaces the depleted source and turns the changeover regulator hand knob to the next standby source.

The Series 8000 system includes a line regulator to allow adjustment of the final delivery pressure. It also includes 6' stainless steel armor-jacketed flexible pigtails with CGA check valves, cylinder isolation and vent valves. This configuration gives the operator the capability to isolate a source from the changeover panel, allowing replacement of the source without having to shut down the system.

High Flow Automatic Changeover System

High Purity Automatic Changeover System

The brass 5028B and stainless steel 5028S Series high purity automatic changeover systems are designed to provide a continuous supply of high purity gases to your lab, processes and instruments. Typically the 5028 Series systems are used with one cylinder per side and because of pressure differential considerations, feature a line regulator.

The standard models come with flexible, all stainless steel pigtails with armor casing, Monel® lined for oxygen service. The CGA connection on each pigtail has a check valve in the gland to prevent contamination and minimize purging requirements. To connect more than one cylinder per side, manifold headers can be ordered separately.

Laboratory Gas Cabinets

Linde's Multi-Gas Point-of-Use Panels

Linde's VersiGas™ Lab System

Protocol Stations

The 5029 Series Protocol Station is a regulator option designed for the convenient wall mounting of any ProStar® regulator to provide ease of use, prevent regulator damage and improve safety. The 5029 Series Protocol Station is available in brass or 316 stainless steel and comes complete with a 3-foot long flexible all stainless steel pigtail with armor casing. The CGA connection on the pigtail has an integral check valve in the gland to prevent internal contamination during cylinder changeouts. Should purging be desired, the gas block comes with a plugged port that can be removed and replaced with a diaphragm valve.

The 5029 Series Protocol Switchover Station combines all of the safety and convenience features of a standard Protocol Station with the added efficiency of a reserve cylinder. The Protocol Switchover Station valve assemblies allow for manual switching between a primary cylinder and reserve cylinder, and isolation of the depleted cylinder allows safe changeouts without backflow of gas through the pigtail.

The 5029 Series Protocol Alarm Station combines all of the safety and features of a standard Protocol Station with the added security of a remote alarm system. The Protocol Alarm Station will provide an audio-visual warning when a cylinder is nearly depleted. The alarm set point is easily adjustable to provide the level of security and notification required. A convenient side port allows the addition of a diaphragm valve for purging when changing cylinders.