Gas Supply for Construction Sites

Linde’s new Productivity-On-Demand (POD™) Portable Microbulk Gas Delivery System provides construction companies, shipbuilders and heavy fabricators with an alternative to facilities and jobsites filled with single cylinders, cylinder packs and portable liquid vessels. As a complete gas supply system that can be moved while full and works where you work, it helps improve productivity, boost efficiency and reduce costs by reducing cylinder handling and change-outs. Innovative and flexible, the POD System ensures a high purity gas supply that’s convenient and dependable.

Improved Productivity – Wherever It’s Needed

The POD System concurrently delivers pure argon and argon/ CO2 blends at 600-950 cubic feet per hour, enough to support 25 or more welders. Measuring 88 inches wide, 55 inches deep and 95 inches high*, this portable solution can be placed right where your welders are working. What’s more, with the available customizable gas distribution panel, it can be configured to meet your fabricating team’s size or specific needs.

Designed for maximum versatility, it can also be configured for use as a stationary high volume gas supply with a single point of use. Depending on configuration, the POD System has a weight range when full of 5,750-8,330 pounds. The new Productivity-On-Demand (POD) Portable Microbulk Gas Delivery System does not require any site preparation. A POD System can be installed practically anywhere at your facility.

Linde-On-Demand's Unique Benefits

![]() Convenience

Convenience

→ Can be moved while full by crane or forklift practically anywhere

→ Uninterrupted gas supply through seamless change-outs

→ Cellular telemetry for supply monitoring and automatic, on-time order generation

→ GPS tracking simplifies asset management

→ Reduced downtime associated with cylinder change-outs

→ Minimizes employee handling and transporting of cylinders

Key POD Features

Multi-channel, battery-operated cellular telemetry unit monitors and reports tank levels to our logistics center for automatic, on-time deliveries.

A top-mounted GPS tracking system working through the cellular telemetry simplifies asset management, and when combined with the DATAONLINE™ platform, enables online tracking and mapping, allowing you to see where PODs are and where they have been.

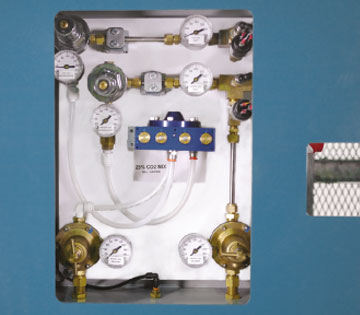

Tamper-resistant, non-mechanical mixer cannot be adjusted by field personnel. Two- and three-gas mixers are available offering a combination of pure argon, C-5, C-10 and C-25. It features a test port for on-site blend verification and adherence to AWS specifications.

The on-board alarm will sound if the mixer reaches the critical low gas pressure point necessary to support blend integrity. When using the available distribution panel, a tethered alarm box can also be set at the worksite to ensure audible notification, even at the busiest facilities.

The switchover box allows the connection and disconnection of units while providing a seamless transition during POD System change-outs. The pressurized quick-connects ensure product integrity throughout the transition, resulting in an uninterrupted supply.