Improved Precision, Stability and Throughput with Variable Volume Piston Cylinders

Typically, manufacturing or monitoring procedures within the HPI industry require both heavy complex hydrocarbons (C3-C10+), light hydrocarbons (C1-C2) and fixed gases all to be in the same matrix or blend, requiring standards that in the past were sub optimized for many applications. Either more than one standard was required for one analytical procedure or lower pressure, smaller batches were prepared in cylinders for different analytical processes. Additionally, some applications require samples to be introduced into high pressure pipelines and analytical systems. Each of these applications can be improved by changing how the gas standards are manufactured and used in the process.

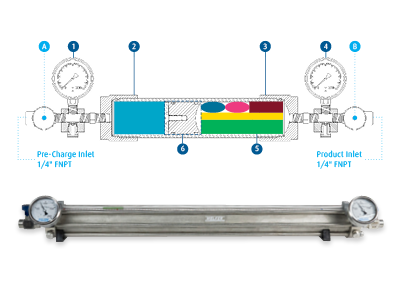

Linde has developed a solution for these manufacturing and analytical challenges. By combining commercially available DOT, OSHA and CGA-compliant variable volume piston cylinders with proprietary blending and analytical techniques, Linde can provide the most repeatable and stable liquified gas mixtures in the industry.

Customized Blends

- Customer-defined components

- Can include permanent light hydrocarbon and heavy hydrocarbon gases all in one mix – will not separate as product is consumed

- Can include sulfur products (requires specific piston cylinder)

- Can include alcohols, aldehydes and cyclic compounds

- Customer-specified pressure pad, typically helium

- Customer-specified delivery pressure, up to 1000 psi

Maintaining Mixture Integrity

Constant or controlled pressure is the key to stabilized liquid blends. Pressure is maintained on the gas mixture by a piston. As the gas mixture is consumed in the analytical or manufacturing process, the piston moves and maintains the head pressure on the mixture, ensuring mixture integrity. Linde has manufactured liquid blends with up to 50 different components. Our ISO 9001 and 17025 accreditation ensures the highest quality reference and process mixtures available in the market.