Maximize Collection Efficiency with Walk-In Clean Air Stations

When it comes to controlling air quality, welding fume extraction and grinding dust collection are becoming increasingly important in industrial production. Welders and other employees in the facility can be exposed to these dangerous particles and fumes, which can cause permanent damage to their health if not collected and filtered from the air.

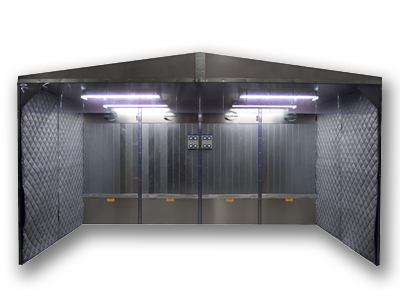

Operators that work on large, oversized parts oftentimes cannot easily place these parts under a fume arm or on top of downdraft table. Therefore, work zones may be under protected and operator health can be affected. In addition to portable fume collectors and downdraft tables, walk-in clean air stations can help address these challenges in your efforts to protect workers. Walk-in clean air stations are self-contained filtration rooms that enclose applications generating harmful dust, smoke or fumes.

Isolating small areas or processes within a larger facility can be a cost-effective means to control plant air quality. Enclosing a dust source in a walk-in booth or enclosure, helps minimizes the amount of air that needs to be cleaned, keeping the cost at a minimal level. Dust control enclosures help encapsulate processes where pollutants are blown around and dispersed within a facility by cross drafts, compressed air or rotating equipment.

Available from Linde, DualDraw® walk-in clean air stations’ large, three-sided, self-contained filtration rooms are designed to help address some of the more challenging dust- and fume-producing applications. Ideal for containing dust and fume from welding, grinding and plasma cutting operations, they use a modular fan and motor system to pull contaminated air through a perforated back Power Wall, assisted by an optional push of clean air from a proprietary slotted vertical tube system on the front of the unit.

Each walk-in clean air station incorporates the patented airflow design combined with a filter system configured for the customer application. Shipped in sub-assemblies, the units offer simple set-up, allowing operators to get up and running quickly. For applications with overhead crane or hoist requirements, units can be configured with chain slots. Start-up and operator training is available to be performed on-site or remotely by experienced technicians.

Features of Walk-In Clean Air Stations

- Self-contained solution; no outdoor exhausting necessary

- Standard sizing starts at 8’W x 8’H x 8’D and can be modified based on application either smaller or larger in 2’ increments.

- Filter system options include combustible and non-combustible dust collection, , smoke/fume removal, HEPA

- Helps meet indoor air quality OSHA Standard 1910.1000 in addition to combustible dust regulatory standards such as NFPA 654 and 484

- Most units do not require water or compressed air and come with easy to maintain, front accessible clean-out trays