Linde’s StarSolver™ Productivity Enhancement Program for CNC Cutting Systems Helps Improve Efficiency and Reduce Costs

Regardless of the size of your business, process and facility optimization is essential to enhancing profitability and maintaining competitiveness in the manufacturing industry. Without a fully optimized manufacturing process, individual machines and entire manufacturing operations can fall short of their full productivity and cost-effectiveness goals and potentials. But figuring out just what your facility needs can be a daunting task.

Linde’s Metfab Productivity Specialists (MPS) team has answers to your toughest process improvement questions. Trained in the latest technologies, these specialists bring expertise, combined with decades of insight and experience, to help customers solve even the most challenging productivity shortfalls.

Increase Productivity and Improve Quality

Degradation in your overall system performance can lead to a loss of productivity, poor product quality and an increase in waste and rejected materials — all of which jeopardize your profitability. Through Linde’s StarSolver™ Productivity Enhancement Program, the MPS team will design a program tailored to your operational needs to help solve even your most challenging problems.

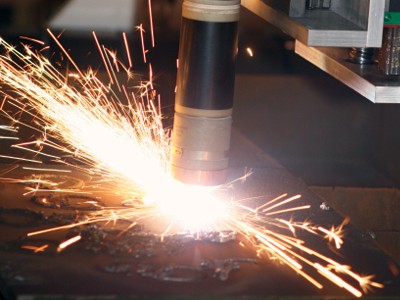

The StarSolver program incorporates process analyses and facility evaluations, with as little disruption to your work as possible. The team’s goal is to identify the causes for shortfalls as well as opportunities to improve production throughput while minimizing reject rates and labor costs. In addition to evaluating your gas and supply, system operation and customer experience, the program also includes an evaluation of operational machinery. The MPS team can analyze all makes and models of cutting equipment and determine what is needed to repair, retrofit and/or modify old machines to “like-new” performance.

Benefits of the StarSolver Productivity Enhancement Program for CNC Cutting Systems

- Determine repair, retrofit or modification needs

- Identify equipment potential failure

- Optimize and improve processes

- Uncover operator errors

- Improve cutting productivity

- Reduce post-cut cleanup

- Decrease pierce time

- Increase facility efficiency

Schedule a StarSolver Audit for Your Shop Today