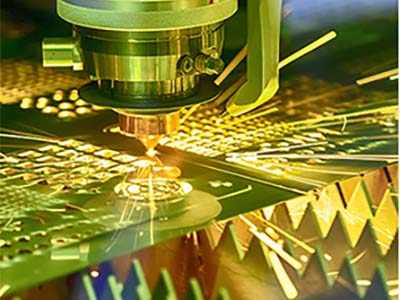

OEM Parts Maintain Laser Performance, Maximize Productivity

Apr 19, 2022, 15:44 PM

by

System

Using aftermarket parts versus OEM parts can reduce your laser’s cutting capabilities and lead to significant service issues.

Just as with virtually every industry, the cost of consumable parts for laser cutting systems has fallen drastically in recent years.

“There are a lot of cheap nozzles out there for CO2 and fiber lasers,” says Jason Hillenbrand, Laser Product Manager for Amada America, which designs and manufactures laser cutting equipment and additional precision products for sheet metal fabrication. “You can buy nozzles for as little as 10 dollars, depending on the specific type.” Amada’s laser nozzles are built from proprietary designs specified by its engineers, such as the chemical composition of the tip and cone curvature, to ensure optimal cutting performance. Replacing OEM nozzles, lenses and mirrors and other laser consumables with aftermarket models that are not to Amada OEM specifications can reduce the laser unit’s cutting capabilities and lead to significant service issues, Hillenbrand says.

One of those issues can involve the gases used to power the laser cutting. Praxair produces LaserStar™ gases to meet the laser industry’s stringent requirements. Gases are constituted to work properly with the laser nozzle’s chemical composition, which can vary significantly between OEM and aftermarket parts. Aftermarket tips that do not match chemical composition can reduce the laser’s effectiveness and allow impurities to pass through the system and accumulate on other parts, such as the mirrors and lenses. “Using the proper nozzles reduces consumption of gases such as nitrogen because the nozzle better directs the flow of gas, which affects the cutting quality,” Hillenbrand says. “It also eliminates disturbances that interrupt the flow of gas, keeping the cutting edge smoother and ultimately producing a cleaner product.” Praxair works closely with customers such as Amada to develop high-purity gases that assure peak laser performance, maximize operating duty cycle and reduce maintenance costs.

“A customer bought the machine for performance, and it’s not worth it to use aftermarket parts instead of OEM parts,” says Larry Cherne, Marketing Manager, Laser Gases for Praxair. “You lose the savings so quickly because of reduced cutting quality and performance, along with the service calls to figure out what’s wrong. OEM parts keep the machine performing as it’s intended.”