Increase Production and Reduce Welding Costs with the LI’L RUNNER™ Automatic Fillet Welder

Each year, manufacturers are having to adapt to labor shortages, production inefficiencies and pressing market demands, prompting a greater need for flexibility on the shop floor. While there is much at play when it comes to operational flexibility, having the proper machinery and equipment to facilitate production goals is imperative. Welding automation can help companies gain greater productivity and repeatable, high-quality results in their welding operations, while controlling costs.

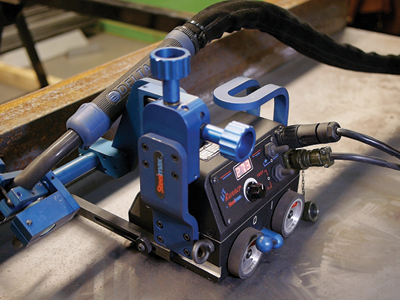

With its lightweight, compact design, all-wheel drive and magnetic force traction, the LI’L RUNNER™ Automatic Fillet Welder by STEELMAX® provides stable, non-stop travel at user-regulated speeds. Reliable traction and consistent speed enables the LI’L RUNNER to produce weld bead geometry to your exact specifications, reducing costly over-welding and decreasing filler metal use by up to 60 percent. The LI’L RUNNER™ welder creates consistent, high-quality welds and helps deliver savings on any job that demands continuous welds, in a fraction of the time required by hand welding.

Great Flexibility in a Small Package

Weighing just over 17 pounds, the LI’L RUNNER™ can be carried virtually anywhere on the job. The positive magnetic traction provides the versatility to handle long, straight continuous welds or permit out-of-position use, including on a vertical piece of steel. The LI’L RUNNER also finishes lids and bottoms with no attachment, and horizontal seams are completed with an optional arm attachment. All of these welds can meet your specifications with minimal distortion thanks to the LI’L RUNNER welder’s consistent heat input and efficient use of filler metal.

The LI’L RUNNER moves welding operators away from heat and fumes, reducing their exposure, as well as reducing the fatigue and repetitive stress associated with hand welding. With its speed, reliability and flexibility in producing high-quality continuous welds, the LI’L RUNNER Automatic Fillet Welder can help you keep productivity moving.

Top Features

- Lightweight, compact design

- Digital LED display for accurate adjustment of travel speed

- Positive magnetic traction allows out-of-position use

- Maintenance-free 4-wheel drive with worm gear reduction

- Rapid clamp torch holder mechanism accommodates variety of MIG/MAG welding torches

- Precise welding torch adjustment with screw-drive cross slide

- Durable aluminum cast housing

Primary Benefits

- Helps to increase arc time by minimizing starts and stops on long continuous welds

- Can reduce filler metal use by up to 60 percent – minimmizes over-welding

- Faster travel speed and consistent heat input lessen distortion

- Precise travel speed and torch angle reduce weld defects and costly rework

- Quick setup means more production time

- Helps improve work environment by removing operator from heat and fumes

Quick, Easy Setup and Operation

You have complete command of your welding process from start to finish with the LI’L RUNNER automatic welding machine. Its positive magnetic traction and self-guiding roller arms minimize the need for an operating track. The magnetic-adhesion release lever permits easy placement and adjustment on a work piece, reducing set-up time and improving productivity.

The LI’L RUNNER rapid clamp torch holder mechanism works with all major brands of MIG/ MAG welding torches and is coupled with a cross slide screwdriver for precise torch adjustment. Combine this exact torch placement with faster, user-regulated speed, and the LI’L RUNNER can significantly reduce weld defects and costly piece rework compared with hand welding.

Boost Your Productivity with Linde

Linde is an exclusive distributor of LI’L RUNNER by STEELMAX®. To learn more about how the LI’L RUNNER can save time, conserve resources and boost your productivity, contact your local Linde representative today at 800.225.8247.