Stargon™ VS Welding Gas Blend

Argon/Helium/Carbon Dioxide Blend for Carbon Steel MIG Welding

Linde's Stargon™ VS is an optimized blend of argon, helium and carbon dioxide formulated to perform well with all solid and metal-cored wires. It can be used to join plain carbon steel, coated or electro-galvanized steel, and may be suitable for some stainless steel applications in various industrial applications. Versatility is the key feature of Stargon VS. It is an excellent choice for short-circuiting, spray or pulsed spray welding for a wide variety of applications. When welding over moderate rust, mill scale, or galvanized coating, the stable arc characteristics produced by Stargon VS result in a weld with little to no porosity and excellent bead appearance. Any fine spatter produced will typically not adhere to the work piece. This reduces, or can eliminate, postweld cleaning. The unique blend of gases in Stargon VS produce a stable metal transfer over a wide range of operating conditions. Welding can be done at high deposition rates and fast travel speeds without sacrificing weld quality or bead appearance, and will not increase the low spatter levels of Stargon VS.

Features and Benefits

| Product Features | Benefits |

|---|---|

| Versatile: One blend for many applications | May be used with a range of consumable and material types May be used with different forms of metal transfer |

| Good wetting characteristics Low oxidation level | Improved heat transfer using helium Greater arc stability with low volume CO2 addition Excellent weld properties |

| Better stability over a range of surface conditions | Reduced porosity levels made possible on galvanized sheet material Less spatter on surfaces with light oil/scale |

Buy Stargon VS Now

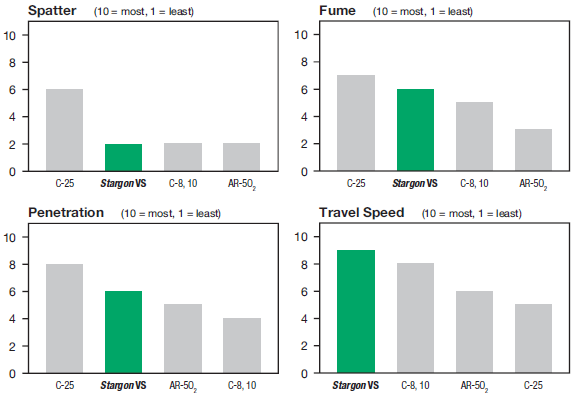

Comparisons

Below are comparisons between shielding gas blends over a range of operating conditions. They are intended to provide suggestions for gas blend selection based on the criteria indicated.

Note: The selection of the appropriate shielding gas can be complex due to the variety of operating variables (base metal chemistry and thickness, transfer type, wire selection and welding position). Consult your Linde representative to help you choose the best gas for your application.

Welding Conditions Selection Table

| Wire Diameter (in) | Process | Wire Feed Speed (ipm) | Current Level (amps) | Voltage (volts)* |

|---|---|---|---|---|

| 0.035 | Short Circuit | 275-400 | 100-175 | 16-20 |

| 0.035 | Spray | 350-600 | 175.25 | 26-30 |

| 0.035 | Pulsed Spray | 300-500 | 125-225 | 20-26 |

| 0.045 | Short Circuit | 150-280 | 100-175 | 17-20 |

| 0.045 | Spray | 250-400 | 150-280 | 24-30 |

| 0.045 | Pulsed Spray | 250-400 | 150-280 | 24-28 |