StarGold™ O-2 and O-5 Welding Gas Blends

Linde’s StarGold argon/oxygen blends are most widely used with conventional and pulsed spray transfer on clean (little or no scale or residual oil), plain carbon and ferritic stainless steels. These blends (typically 2 or 5% oxygen by volume) provide good arc stability and very low levels of spatter.

As the oxygen component increases, the minimum spray transition current decreases and the fine droplet spray operating range broadens. Higher oxygen levels also increase weld puddle fluidity (and potentially travel speed) and improve bead wetting characteristics.

Low levels of welding fume are produced with this family of gas blends. Argon/oxygen blends are not recommended for short-circuiting transfer due to the increased chance of lack-of-fusion defects.

Oxygen blends with greater than 5% oxygen exhibit greater tendency toward undercutting, poor bead shape and difficulty in puddle control. Gap-bridging ability is reduced. Oxide build up on the bead surface may also be excessive, which can be problematic when the weldment is painted.

The StarGold argon/oxygen blends from Linde can be readily supplied as pre-mixed liquid in portable containers for reduced gas supply costs.

Linde’s StarGold O-2 Gas Blend

Features

Primarily used for conventional and pulsed spray transfer of carbon and low alloy steels:

- Low oxidizing potential

- Specified in some military applications

Benefits

- Good arc stability and puddle fluidity

- Minimum alloy loss; good mechanical properties

- Low welding fume generation

Linde’s StarGold O-5 Gas Blend

Features

Primarily used for conventional spray transfer for carbon steels:

- High level O2 addition

- Improved puddle fluidity

Benefits

- Very good arc stability; low fume levels

- More fluid, but controllable weld puddle

- Faster travel speeds possible in some applications

- Can be used with metal-cored wires

O2 Applications

- 409SS

- Mufflers and exhaust system components

- Spray arc welding of carbon steels used in military applications (some higher strength materials)

- Farm equipment

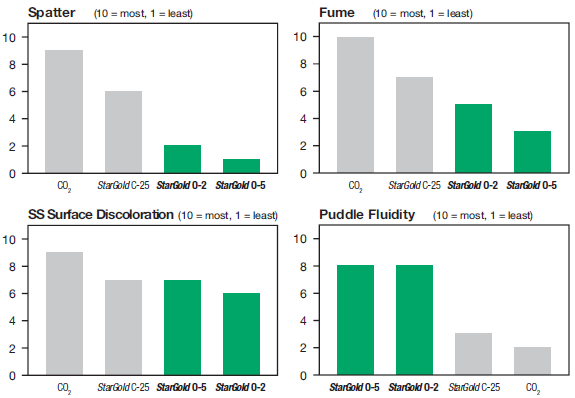

Comparisons

Below are comparisons between shielding gas blends over a range of operating conditions. They are intended to provide suggestions for gas blend selection based on the criteria indicated.

Note: The selection of the appropriate shielding gas can be complex due to the variety of operating variables (base metal chemistry and thickness, transfer type, wire selection and welding position). Consult your Linde representative to help you choose the best gas for your application.

Welding Conditions Selection Table

| Wire Diameter (in) | Process | Wire Feed Speed (ipm) | Current Level (amps) | Voltage (volts)* |

|---|---|---|---|---|

| .035 | Spray Pulsed Spray | 350-500 275-400 | 190-240 100-150 | 26-27 17-21 |

| .045 | Spray Pulsed Spray | 300-475 200-250 | 260-340 175-200 | 28-31 19-23 |

| .063 | Spray | 185-245 | 310-371 | 28-31 |

* Voltage level for 60 Hz power supply. Add 2-3 volts for 50 Hz models.