StarGold™ C-15 and C-20 Argon Carbon Dioxide Blends

Linde’s argon mixtures containing more than 15% but less than 20% CO2 by volume (StarGold C-15 and C-20) can be used with a variety of wire types when joining carbon and low alloy steels. Within the range of these blends, it is still possible to obtain a fine droplet spray transfer with minimum spatter and high deposition rates while using slightly higher voltage levels.

These blends work well for joining sheet metal as well as thicker plate. Increasing the CO2 content increases penetration and generally produces greater travel speeds. For thinner material, it is important to balance increased penetration against the potential for possible burnthrough. Increasing the CO2 content of the blend generally results in a more convex weld bead and greater surface oxide, but wetting of the weld metal is enhanced. Slightly above 20% CO2 conventional spray transfer can not be readily achieved, causing increased spatter while improving sidewall fusion.

Linde’s StarGold C-15 and C-20 gas blends can be used with solid, some specially formulated flux-cored, and most metal-cored wires. If flux-cored wire is selected, care must be taken in the choice of the wire and gas blend combination to ensure compatibility and optimum weld performance and properties.

Refer to manufacturer’s literature for recommended shielding gas and filler metal combination.

Product Features

- Optimized CO2 content for wire type and application

- Can be used in short, spray, pulsed-spray and globular transfer with either solid, metal-cored or flux-cored wires

- Can be used with some flux-cored wires

- Large operating range for many applications

- Ideal for bulk supply

Product Benefits

- Improved arc performance over some minor surface scale and oil

- Minimum spatter levels

- High potential travel speeds

- Improved penetration

- Low welding fume levels compared with standard CO2 shielded cored wires

- High deposition efficiency

- Can optimize process for application

- Reliable, low cost supply

- Reduced gas costs when supplied as liquid

Typical Applications

- Storage racks for automotive industry

- Railcar center sills and side panels (metal and flux-cored wires)

- Backhoes and front-end loaders

- Wheel rims for cars and trucks

- Motorcycle and truck frame fabrication; engine cradles

- Farm implements

Comparisons

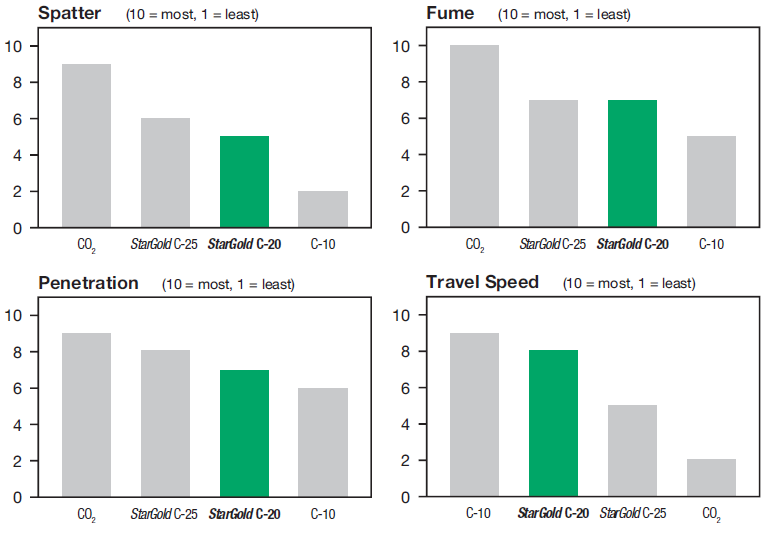

Below are comparisons between shielding gas blends over a range of operating conditions. They are intended to provide suggestions for gas blend selection based on the criteria indicated.

Welding Conditions Selection Table

| Wire Diameter (in) | Process | Wire Feed Speed (ipm) | Current Level (amps) | Voltage (volts)* |

|---|---|---|---|---|

| 0.035 | Short Circuit Spray | 150-280 350-550 | 100-175 180-230 | 17-21 27-29 |

| 0.045 | Short Circuit Spray | 150-280 300-500 | 100-175 250-310 | 17-21 28-31 |

| 0.063 | Spray | 150-300 | 250-400 | 30-33 |

* Voltage level for 60 Hz power supply. Add 2-3 volts for 50 Hz models.