Categories

Welding Wire & Electrodes

Welding Wire Solid Welding Wire Flux-Cored Welding Wire Metal-Cored Welding Wire Submerged Arc Welding Wire

Welding & Cutting Equipment

Oxy Actylene Welding & Cutting Lighters & Flints Oxy Acetylene Welding & Cutting Torches Oxy Acetylene Welding & Cutting Outfits Quick Connectors Oxy Acetylene Welding & Cutting Torch Attachments Flashback Arrestors Oxy Acetylene Welding & Cutting Torch Handles Burning Bars & Lances Oxy Acetylene Cutting Machine Accessories Oxy Acetylene Cutting Machines

Abrasives

Safety & PPE

Protective Clothing Welding & Fire Resistant Clothing High Visibility Vests & Jackets Aluminized Clothing

Welding Helmets & Lenses Welding Lenses, Filters & Covers Welding Helmets Welding Helmet Replacement Headgear Welding Helmet Accessories

Welding & Cutting Consumables

MIG Welding Consumables MIG Contact Tips MIG Nozzles MIG Diffusers MIG Liners MIG Insulators MIG Drive Rolls Mig Conductor Tubes MIG Consumable Kits

TIG Welding Consumables Tungsten Electrodes TIG Cups TIG Collet Bodies TIG Collets TIG Torch Back Caps TIG Insulators & Gaskets TIG Gas Lenses TIG Consumables Kits TIG Nozzles

Plasma Cutting Consumables Manual Cutting Consumables Manual Plasma Torch Electrodes Manual Plasma Torch Nozzles Manual Plasma Torch Shield Caps Manual Plasma Torch Tips Manual Plasma Torch Retaining Caps Manual Plasma Torch Swirl Rings Manual Plasma Torch Start Cartridges Manual Plasma Torch Consumables Kits Manual Plasma Torch Deflectors Manual Plasma Torch O-Rings Manual Plasma Torch Diffusers Manual Plasma Torch Collets

ProStar Circular Cutting Systems

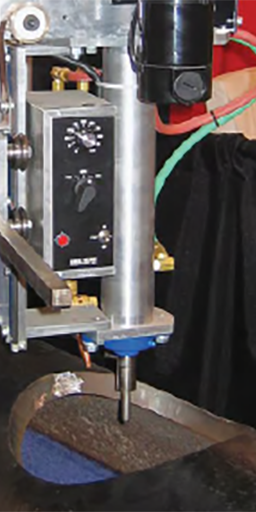

The PRS RB2500 and PRS RB3500 oxy-fuel circular cutting systems come with the same standard cutting diameter, rise-and-fall cam action, vertical/horizontal rack and pinion adjustments, two hose machine torches with adjustable heads (beveling attachment), variable speed clockwisecounterclockwise rotation with no oxyfuel hose and electrical cable wrap up.

The only differences in the PRS RB2500 and the RB3500 are in how and where the machines will be used for cutting.

PRS RB3500 shown with optional equipment. Hillside attachment available for PRS RB3500: Part No. PRS RB3550.

PRS RB3500 Oxy-Fuel Circle Burner

| Cutting Diameter | Beveled holes 1.5” (38 mm)–42” (1066 mm) Standard holes 4” (101 mm)–42” (1066 mm) |

|---|---|

| Mounting | Column and boom, manipulator, or side-beam carriage |

| Rise and Fall Cam | 0”–7” (0–177 mm) |

| Applications | Burning holes in tank heads, tanks, and pipe |

| Advantages | Designed for large scale and semi-automated operations |

PRS RB2500 Oxy-Fuel Circle Burner

| Cutting Diameter | Beveled holes 1.5”–42” (38mm–1066 mm) Standard holes 4”–42” (101 mm–1066 mm) |

|---|---|

| Mounting | Self-supported manually operated magnetic base |

| Rise and Fall Cam | 0”–7” (0–177 mm) |

| Applications | Burning holes in tanks |

| Advantages | Mobile design for versatility and on-the-spot cutting |