What is StarGold C-5 and C-10?

Argon mixtures containing from 5-10% CO2 by volume are used for conventional and pulsed spray transfer welding of carbon and low-alloy steels. Welds are less oxidized than those made with argon/oxygen blends and the penetration profile is broader. Bead shape is good. Weld metal mechanical properties are excellent. Welding fume levels are low with both solid and metal-cored wires.

These mixtures can also be used for short-circuiting metal transfer on thin gauge material. At lower CO2 levels, care should be taken in selection of welding parameters in the short-circuiting mode to ensure adequate heat is available for acceptable penetration.

These gas blends can also be used with specially designed low fuming, flux-cored wires.* Depending upon the wire selected, excellent all-position performance can be obtained with a minimum level of welding fume. In some applications, when either metal-cored or these special all-position flux-cored wires are used with Ar/low CO2 blends, it is possible to complete multiple pass weld procedures without chipping or deslagging between passes.**

Argon/carbon dioxide shielding gases can be readily mixed from liquid (bulk) storage tanks for reduced gas supply costs, or supplied premixed in standard high-pressure cylinders.

* Always refer to the wire manufacturer’s recommendation for shielding gas selection.

** Up to three passes.

C-5 Features

Linde’s StarGold C-5 gas blend is primarily used for pulsed spray transfer welding of plain carbon and low-alloy steels:

- Lower CO2 content

- High argon content

C-5 Benefits

- Faster freezing weld puddle for all-position welding

- Good arc starting and stability in pulsed spray

- Excellent weld metal mechanical properties

- Low spatter and fume levels

C-10 Features

Linde’s StarGold C-10 gas blend is primarily used for spray transfer with solid and metal-cored wires:

- Slightly increased CO2 content for improved puddle fluidity and broader penetration

- Improved short arc performance

C-10 Benefits

- Improved bead wetting and shape with fewer weld defects

- Good arc stability

- Lower fume levels compared with other argon/carbon dioxide blends and CO2

- Controlled penetration for good gap bridging

- Offer improved penetration when compared to Ar/O2 blends

Typical Applications for C-5

For all-position pulsed spray welding of thin and heavy carbon and low-alloy steels such as HY-80.

Typical Applications for C-10

- For conventional spray arc welding using either solid, metal cored, or specially developed flux-cored wires, of farm implements, machinery and structural members where broader penetration is desired.

- For use with metal-cored wires in all applications. Arc stability is excellent and penetration is improved over argon blends with less CO2 or with oxygen additions.

- For bridging gaps on light

Welding Conditions Selection Table

| Wire Diameter (in) | Process | Wire Feed Speed (ipm) | Current Level (amps) | Voltage (volts)* |

|---|---|---|---|---|

| 0.035 | Spray Pulsed Spray | 350-550 275-400 | 175-220 100-150 | 26-28 18-22 |

| 0.045 | Spray Pulsed Spray | 300-500 200-250 | 260-320 175-200 | 27-30 20-24 |

| 0.063 | Spray | 150-300 | 250-400 | 29-32 |

* Voltage level for 60 Hz power supply. Add 2-3 volts for 50 Hz models.

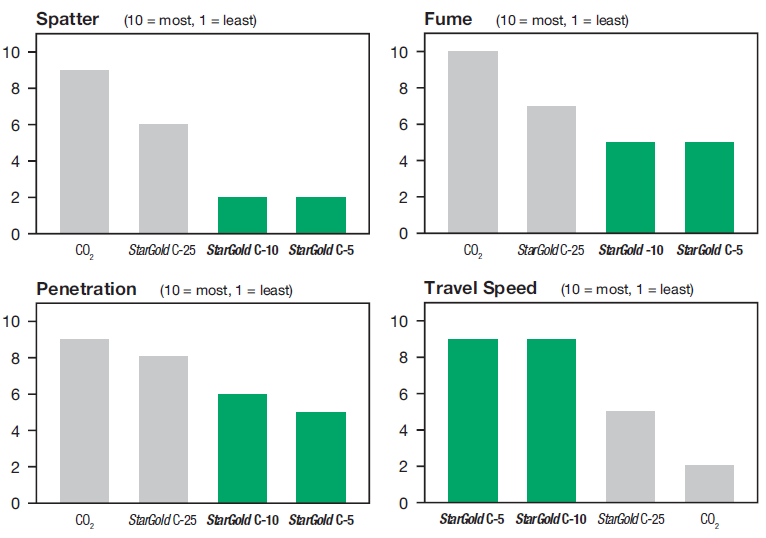

Comparisons

Below are comparisons between shielding gas blends over a range of operating conditions. They are intended to provide suggestions for gas blend selection based on the criteria indicated.

Note: The selection of the appropriate shielding gas can be complex due to the variety of operating variables (base metal chemistry and thickness, transfer type, wire selection and welding position). Consult your Linde representative to help you choose the best gas for your application.