Page 170 - ProStar Product Guide

P. 170

SAFETY PRODUCTS

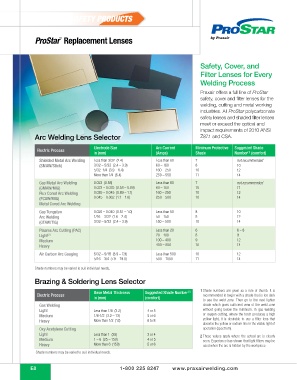

ProStar Replacement Lenses

™

Safety, Cover, and

Filter Lenses for Every

Welding Process

Praxair offers a full line of ProStar

safety, cover and filter lenses for the

welding, cutting and metal working

industries. All ProStar polycarbonate

safety lenses and shaded filter lenses

meet or exceed the optical and

impact requirements of 2010 ANSI

Arc Welding Lens Selector Z87.1 and CSA.

Electrode Size Arc Current Minimum Protective Suggested Shade

Electric Process

[1]

in (mm) (Amps) Shade Number (comfort)

Shielded Metal Arc Welding Less than 3/32 (2.4) Less than 60 7 not recommended

(SMAW/Stick) 3/32 – 5/32 (2.4 – 3.9) 60 – 160 8 10

5/32–1/4 (3.9 – 6.4) 160 – 250 10 12

More than 1/4 (6.4) 250 – 550 11 14

Gas Metal Arc Welding 0.023 (0.58) Less than 60 7 not recommended

(GMAW/MIG) 0.023 – 0.035 (0.58 – 0.89) 60 – 160 10 11

Flux Cored Arc Welding 0.035 – 0.045 (0.89 – 1.1) 160 – 250 10 12

(FCAW/MIG) 0.045 – 0.062 (1.1 – 1.6) 250 – 500 10 14

Metal Cored Arc Welding

Gas Tungsten 0.020 – 0.040 (0.51 – 1.0) Less than 50 8 10

Arc Welding 1/16 – 3/32 (1.6 – 2.4) 50 – 150 8 12

(GTAW/TIG) 3/32 – 5/32 (2.4 – 3.9) 150 – 500 10 14

Plasma Arc Cutting (PAC) Less than 20 6 6 – 8

Light 20 – 100 8 9

[2]

Medium 100 – 400 9 12

Heavy 400 – 800 10 14

Air Carbon Arc Gouging 5/32 – 5/16 (3.9 – 7.9) Less than 500 10 12

5/16 – 3/4 (7.9 – 19.0) 500 – 1000 11 14

Shade numbers may be varied to suit individual needs.

Brazing & Soldering Lens Selector

1 Shade numbers are given as a rule of thumb. It is

[1]

Base Metal Thickness Suggested Shade Number

Electric Process recommended to begin with a shade that is too dark

in (mm) (comfort)

to see the weld zone. Then go to the next lighter

Gas Welding shade which gives sufficient view of the weld zone

Light Less than 1/8 (3.2) 4 or 5 without going below the minimum. In gas welding

Medium 1/8-1/2 (3.2 – 13) 5 or 6 or oxygen cutting, where the torch produces a high

Heavy More than 1/2 (13) 6 to 8 yellow light, it is desirable to use a filter lens that

absorbs the yellow or sodium line in the visible light of

Oxy Acetylene Cutting operation (spectrum).

Light Less than 1 (25) 3 or 4 2 These values apply where the actual arc is clearly

Medium 1 – 6 (25 – 150) 4 or 5 seen. Experience has shown that light filters may be

Heavy More than 6 (150) 5 or 6 used when the arc is hidden by the workpiece.

Shade numbers may be varied to suit individual needs.

E8 1-800 225 8247 www.praxairwelding.com