Page 138 - ProStar Product Guide

P. 138

High Deposition Rates and

Excellent Weld Quality for STARGON VS GAS BLEND

IS OPTIMAL FOR:

Carbon Steel MIG Welding Metal cored and solid wires

All-position welding (F1, F2, F3, F4)

Praxair’s Stargon VS welding blend High arc stability at both low and

™

helps improve throughput and high amperages

Jobs requiring changes in metal

productivity with reduced overall cost transfer modes and electrode types

Stargon VS Welding Blend

LEFT

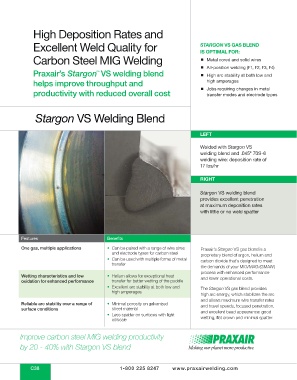

Welded with Stargon VS

welding blend and .045" 70S-6

welding wire: deposition rate of

17 lbs/hr

RIGHT

Stargon VS welding blend

provides excellent penetration

at maximum deposition rates

with little or no weld spatter

Features Benefits

One gas, multiple applications • Can be paired with a range of wire sizes Praxair’s Stargon VS gas blend is a

and electrode types for carbon steel

proprietary blend of argon, helium and

• Can be used with multiple forms of metal carbon dioxide that’s designed to meet

transfer

the demands of your MIG/MAG (GMAW)

process with enhanced performance

Wetting characteristics and low • Helium allows for exceptional heat and lower operational costs.

oxidation for enhanced performance transfer for better wetting of the puddle

• Excellent arc stability at both low and The Stargon VS gas blend provides

high amperages

high arc energy, which stabilizes the arc

and allows maximum wire transfer rates

Reliable arc stability over a range of • Minimal porosity on galvanized and travel speeds, focused penetration,

surface conditions sheet material

and excellent bead appearance: good

• Less spatter on surfaces with light

oil/scale wetting, flat crown and minimal spatter.

Improve carbon steel MIG welding productivity

by 20 - 40% with Stargon VS blend

C38 1-800 225 8247 www.praxairwelding.com